FAW 10cbm rubbish compactor truck, FAW 4×2 left hand drive truck chassis, equipped with XICHAI 180HP diesel engine, FAST model 6-shift transmission gear. CAN-BUS control system for easy operation. All painting and logos based on customers requirement. FAW back-loading compression garbage truck is suitable for the garbage collection and transportation in good conditions places, such as urban and rural streets, large factories, residential areas and school.

Payment:

T/T, West UnionProduct Origin:

China CEECShipping Port:

China Main PortLead Time:

20 DaysWork capacity:

10CBMTruck model:

CEEC5180ZYSEngine power:

180HPEngine type:

CA6DF2D-18Axle drive:

4X2, LHDGear box:

FAST 8F & 1RRemarks:

CAN-BUS smart control box for workingGarbage compactor truck is composed of hermitical garbage box, hydraulic system and operating system, which could apply pressure to the waste to break down bulky items, to load and transport more garbage by one time. Dirty liquid flows into waste sink, perfectly preventing repollution. When arriving at destination, the garbage can be dumped completely. Customized newly designed FAW garbage compactor truck is ideal solution for solid waste collection. FAW Garbage compactor (also called FAW waste compactor truck, FAW garbage compactor truck, FAW trash compactor, FAW refuse collection truck, FAW compactor garbage truck, FAW rubbish truck, FAW bin wagon, FAW dustcart, FAW bin lorry, FAW waste collection vehicle) is designed mainly used in collecting household garbage, commercial waste, nonhazardous and Non-radioactive junk.

● China best FAW rear loader garbage truck factory

● More than 30 years professional manufacturer experience.

● Be designed according to your requirements

● Promptly delivery. any order is welcome.

● 24 month quality guarantee term

Features for FAW 10cbm 8tons waste compactor garbage truck:

★ Adopt world-class FAW brand 4X2 Chassis, High power and Fuel efficiency, Reliability, Uptime

★ All Structural made of High Strength Steel T420 material

★ CAN-BUS electric control and Hydraulic control for easy operation

★ Matched with ISO9001 and CCC quality

★ Optional rear loading device for garbage loading

★ Optional ISUZU GIGA Chassis 4x2, 6x4, 8x4 and engine 6UZ1 and 6WG1

Product Parameters

| Truck Specification | ||

| General | Model | CEEC5180ZYS |

| Chassis Brand | FAW | |

| Overall Dimension | Appro. 8500*2500*3150 (mm) | |

| GVW | Appro. 18000 (kg) | |

| Truck Tare Weight (kg) | Appro. 8000 (kg) | |

| Garbage Container Capacity | Appro. 10CBM | |

| Drive Type | 4x2, Left Hand Drive with power assisted steering | |

| Drive Speed | ≤100Km/h | |

| Cab | Type | One and a half row cab, forward control type, all welded steel cab of tilt type, mechanical cab tilting, rear mechanical cab suspension, adjustable driver seat |

| No of Seats | 3 persons allowed, including driver, with safety belts | |

| Number of Doors | 2 | |

| Air Conditional | With air conditional | |

| Electric System | 24V | |

| Audio System | FM/AM radio, CD/USB player | |

| Engine | Brand | XICHAI |

| Model | CA6DF2D-180 | |

| Fuel Type | Diesel Fuel | |

| Emission Standard | Europe III | |

| Type | Water-cooled four-stroke, direct injection, turbocharged & intercooled | |

| Nos of Cylinder | 6 | |

| Cylinders Arrangement | In-line | |

| Max Output Power | 132 (kw) | |

| Exhaust | 6557(ml) | |

| Max output power/rated speed | 180/2300 (hp/rpm ) | |

| Max torque/rotate speed | 650/1400 (N.m/rpm) | |

| Fuel System | Fuel Tank Capacity | 200Ltr |

| Material | Aluminium fuel tank | |

| Gear Box | Model | FAST |

| Type | Manual | |

| Forward Speeds | 8 | |

| Reverse Speed | 1 | |

| Synchronizer | Yes | |

| Forward Ratios | 8.03 / 5.32 / 3.36 / 2.54 / 2.39 / 1.58 / 1 / 0.76 | |

| Reverse Ratio | 8 | |

| Clutch | Plate's Diameter | ¢380mm |

| Operation System | Hydraulic control with air booster, pushing | |

| Bridge | NOs of Axle | 2 |

| Front Alex | Elliot type, I beam section | |

| Front axle load-bearing (kg) | 6500 | |

| Rear Alex | Single reduction | |

| Rear axle load-bearing (kg) | 13000 | |

| Suspension | Front | 7- Leaf spring with shock absorber |

| Rear | (9+6)-leaf spring | |

| Electric System | Voltage | 24V |

| Battery Capacity (A.h) | 100X2 | |

| Braking System | Full air brake system, split pneumatic circuit , parking spring brake acting on rear axles, exhaust brake | |

| Tire | Type | 10.00R20 |

| Nos | Total 7 pieces, including one spare tire | |

| Solid Waste Compactor Upper-Body Specification | |||

| Garbage Container | Volume | 10CBM | |

| Material | T420 | ||

| Thickness (side/bottom) | 4mm/5mm | ||

| Hydraulic Pump | 1 set | ||

| Multi-way Valve | 1 set | ||

| Flap Cylinder | 2 set | ||

| Lifting Cylinder | 2 set | ||

| Scraper Cylinder | 2 set | ||

| Skateboard Cylinder | 2 set | ||

| Push plate Cylinder | 1 set | ||

| The Electromagnetic Valve | 2 set | ||

| Dirty Tank Volume | 200L | ||

| Filing Time | 8-10s | ||

| Filling Cycle Time | 20-28s each time | ||

| Discharge Type | Flat-pushing and Dumping | ||

| Dumping Time | 15-20s | ||

| Hydraulic Pressure | 16Mpa | ||

| Controlling Way | Manually and Electrical control | ||

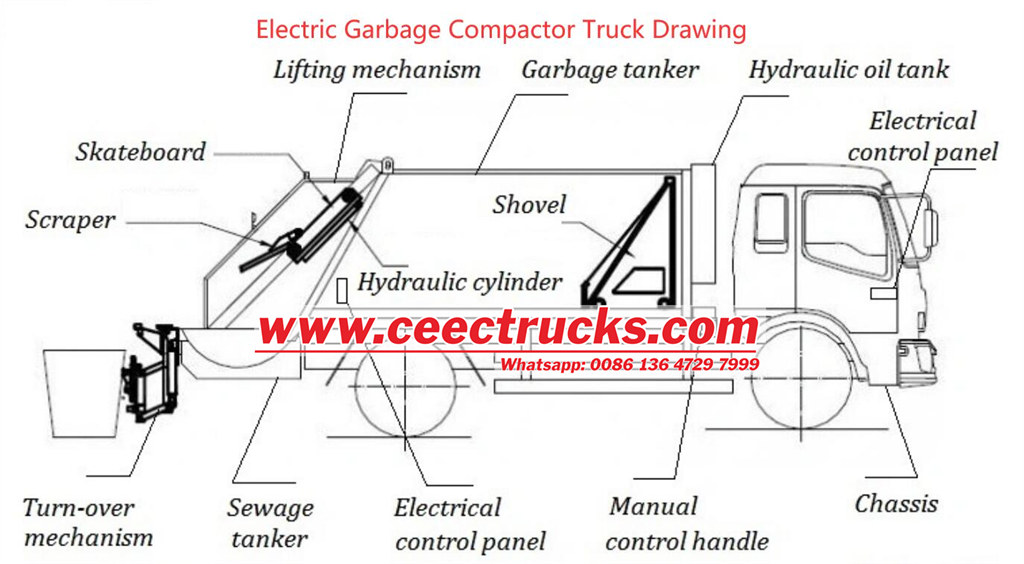

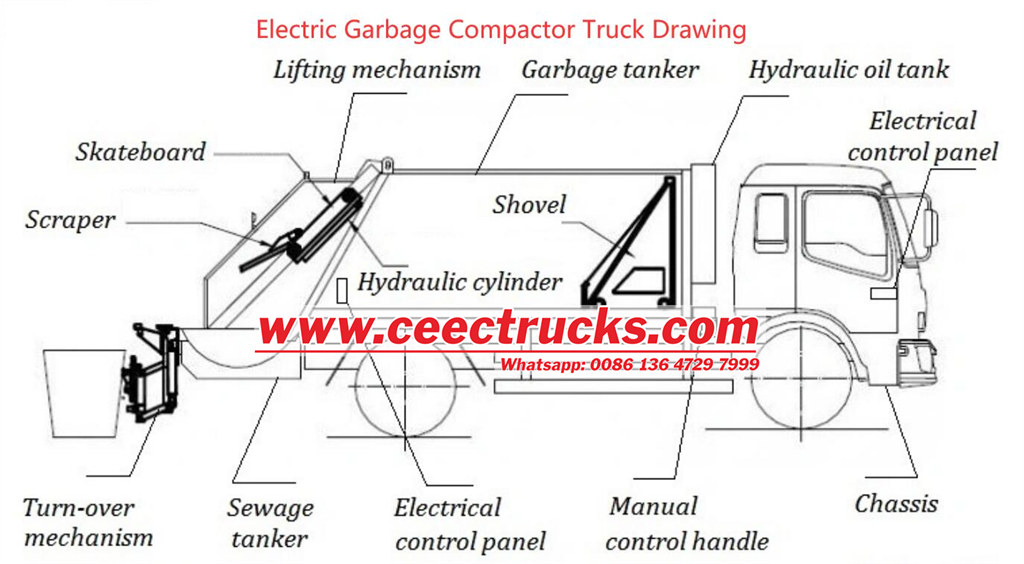

FAW rear loader garbage truck components

The FAW refuse compactor truck designed to fully rely on the advantages of the original of FAW 4x2 Left Hand Drive chassis, fully consider the product's convenience and reliability, also the chassis technology features. The customized 10cbm 13yard garbage compactor body material is international standard high strength carbon steel, both internal and external with anti-rust painting, which can effective to avoid rusting. As for compactor body capacity is 10CBM and safety enough to collecting & transporting waste on customer requirement.

The 4x2 Rear Loader Compactor Truck equipped with new designed CAN control system, multi-function garbage compression system, side climbing ladder, Electric control boxes in cabin and rear of hopper, rear part installed foot pedal, which is customized to collect garbage from different area, two units waste water collection tank can efficiently prevent second pollution during transportation. Cab for the single-row Comfortable seat, nice driving feeling. Therefore, the vehicle is an ideal Fuel Tanker Truck mainly for oil transportation & refueling function.

FAW 4x2 high quality Truck Chassis:

FAW Chassis is adapted to the diesel engine and has a stable power output. The chassis configuration includes a force extractor, a drive shaft, etc., which is used to transfer engine power to the hydraulic system to drive the compression upper body kit.

Compactor Upper Body Kit:

Compactor Body: welded with high-strength steel plates (such as T420 or Q550), the bin is designed as a streamlined or rectangular structure, with a flat bottom and arc-shaped top and side surfaces, which is both lightweight and high-strength, with a compression ratio of 1:2.5 or more1:3 or 1:4.

Push Plate and Compression System: including components such as slide plates, scrapers, and push shovels. The slide plates drive the scrapers to crush and compress the garbage in both directions, and the push shovels evenly distribute the garbage through back pressure to ensure that the bin is fully loaded. And below 3D drawing help you better understand what is rear loader truck drawing.

Hydraulic system: which is the core components of the FAW solid waste compactor truck, including all hydraulic device, such as oil pumps, multi-way reversing valves, Hypres cylinders, etc., the system pressure is usually 16-24Mpa, supporting efficient compression and unloading operations.

Electronic control system: Customized CAN-BUS system or integrated with imported PLC (programmable controller) to achieve automatic control, with emergency braking, explosion-proof valves and other safety protection functions

How does FAW 13yard Garbage Compactor Truck Working

The FAW Garbage Compactor Truck makes use of the special power take off (PTO) to get power from the engine, and then transfer the power to the Gear Pump so to rotate the pump. The pump start working to transfer hydraulic oil to cylinders through pipelines, and cylinders working to make all garbage trucks equipment working, including tailgate, push plate, slide plate, scraper and tilting device. And then realize all function of the garbage compactor truck.

Loading and compression:

After the garbage is poured into the filling hopper, the scraper opens and moves down with the slide plate to insert the garbage, completing the first crushing and compression.

The scraper rotates forward to further compact the garbage, and then the slide plate drives the scraper up to push the garbage into the box. The push shovel gradually retreats under back pressure to ensure that the garbage is evenly filled.

Transfer and unloading:

After FAW rear loader compactor truck is full loading, the garbage box is completely sealed and the sewage flows into the closed sewage tank to avoid secondary pollution during transportation.

When unloading, the filler is lifted and the push shovel pushes the garbage horizontally out of the box. The whole process can be operated with one button in the cab or the rear control box

★ XICHAI engine, super powerful

★ Expert for producing refuse compression trucks over 10 years with good reputation

★ Carbon steel material T420

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for compression garbage trucks

CEEC trucks 5000 square meters workshop for garbage compactor trucks.

Hot Tags :