The ISUZU NPR all-drive garbage compactor truck is a high-efficiency equipment specifically designed for urban waste management. It employs advanced compression technology to significantly reduce the volume of garbage, thereby enhancing transportation efficiency,decreasing the number of transport trips, and lowering operational costs. Built on the Isuzu ELF all-drive chassis, the garbage rear loader is equipped with 190HP 4HK1 engine and the MLD 6-speed transmission, offering robust power performance and stable driving capabilities. With its compact design and easy operation, the ISUZU off-road hydraulic garbage compactor is suitable for garbage collection and transportation in various environments, including cities and townships.

Work capacity:

10CBMTruck model:

CEEC51105QYSCEngine power:

190HPEngine type:

Isuzu 4HK1Axle drive:

4X4,LHDGear box:

Isuzu MLD 6-speed,manualRemarks:

Semi-sealed bucket flip mechanismThe ISUZU NPR all-drive garbage compactor truck is a high-efficiency equipment specifically designed for urban waste management. It employs advanced compression technology to significantly reduce the volume of garbage, thereby enhancing transportation efficiency,decreasing the number of transport trips, and lowering operational costs. Built on the Isuzu ELF all-drive chassis, the garbage rear loader is equipped with 190HP 4HK1 engine and the MLD 6-speed transmission, offering robust power performance and stable driving capabilities. With its compact design and easy operation, the ISUZU off-road hydraulic garbage compactor is suitable for garbage collection and transportation in various environments, including cities and townships.

● China best Isuzu waste compactor truck factory

● More than 30 years professional manufacturer experience

● Be designed according to your requirements

● Professional sales team which will help you to choose suitable truck

● We can offer your a good after-sell service

Specification:

|

ISUZU NPR off-road Rear Load Garbage Truck |

||

|

Chassis Model |

ISUZU ELF 190hp |

|

|

Engine |

Make: ISUZU |

|

|

Diesel 4-stroke direct injection diesel engine |

||

|

Engine model:4HK1-TCG61, Euro 6 emission standard |

||

|

4-cylinder in-line with water cooled, turbocharged and intercooler |

||

|

Maximum output: 189HP/139KW |

||

|

Maximum torque: 507 Nm |

||

|

Displacement: 5.2 L |

||

|

Transmission |

ISUZU MLD, 6 forwards and 1 reverse, manual |

|

|

Drive system |

Left/Right hand drive (off-road system) |

|

|

Chassis |

Frame: U-profile parallel ladder frame and reinforced subframe |

|

|

Front suspension:8 pcs semi-elliptic leaf spring |

||

|

Rear suspension:10+6 pcs semi-elliptic lea spring |

||

|

Fuel tank: 100 L capacity with locking fuel cap |

||

|

Steering |

Power steering, hydraulic steering with power assitance |

|

|

Brakes |

Service brake: dual circuit compressed air brake |

|

|

Parking brake (emergency brake): spring energy, compressed air operating on front shaft and rear wheels |

||

|

ABS |

||

|

Wheels & Tyres |

Tire: 7 pcs 235/75R17.5 |

|

|

Optional:8.25R20 |

||

|

Driver's Cab |

ISUZU NPR wide cab, with three seats, A/C, electric glass, central lock |

|

|

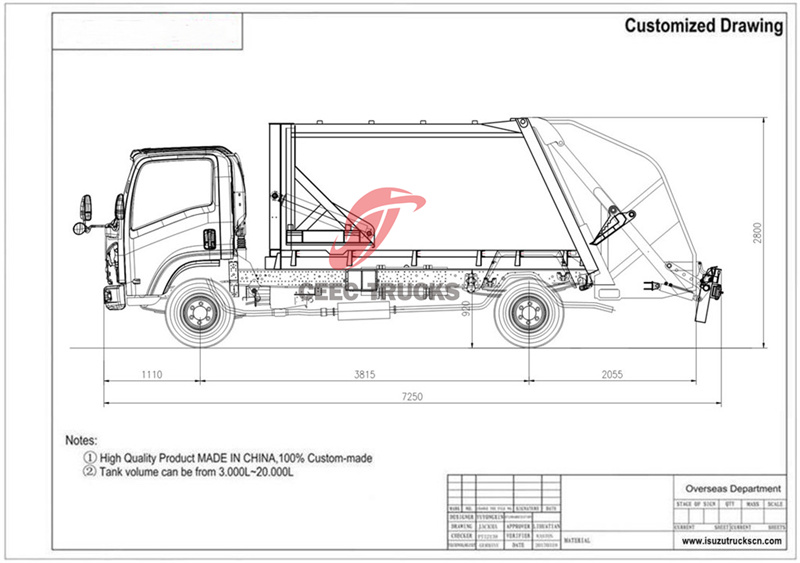

Dimensions mm |

Wheel base |

4175 MM |

|

Overall length |

7400 MM |

|

|

Overall width |

2300 MM |

|

|

Overall height |

2640 MM |

|

|

Weight kg |

Curb weight |

6900 KG |

|

Rated Loading Capacity |

4000 KG |

|

|

Gross vehicle weight(GVW) |

11000 KG |

|

|

Front axle loading capacity |

4000 KG |

|

|

Rear axle loading capacity |

7000 KG |

|

|

Compactor Body |

Volume of body(m3) |

10 |

|

Volume of filler(m3) |

2 |

|

|

Time of one filling cycle(s) |

≤25 |

|

|

Lifting time of filler (s) |

8-10 |

|

|

Time of discharge (s) |

≤40 |

|

|

Pressure of hydraulic system (Mpa) |

18 |

|

|

Front/rear sewage capacity (L) |

250+150 |

|

|

Control system |

CAN-bus (electrical) and manual (hydraulic) |

|

Key manufacturing technology standards:

What high-quality manufacturing processes?

1. Materials and welding processes

Strength steel: The garbage bin and key components use Q345 manganese steel or high-quality carbon steel with a thickness of 5mm. The structural strength is ensured by a fully sealed full welding process.

Lightweight design: The box beam plate structure is adopted to reduce the dead weight while improving the load-bearing capacity.

2. Hydraulic system integration

Precision adjustment: Hydraulic components (such as multi-way valves and cylinders) must be strictly matched, and the pressure valve (16Mpa) must be adjusted before leaving the factory to ensure system stability.

Leakage prevention treatment: The pipeline uses high-density hydraulic oil pipes, and the British DLI sealing ring is used at the interface to reduce the risk of leakage.

3. Sealing and anti-corrosion process

Sewage tank design: Large-diameter discharge ports prevent blockage, and the inside of the box is lined with stainless steel or coated with epoxy coal tar anti-corrosion layer to extend the service life.

Post-welding treatment: Glue the welding parts and spray water-based paint to enhance rust prevention and adhesion.

4. Testing and quality inspection

Before leaving the factory, it must pass load testing (such as compression cycle, unloading stability), sealing testing and road suitability verification to ensure compliance with environmental protection and safety standards.

★ ISUZU 4KH1 diesel engine, super powerful

★ Expert for producing ISUZU rear loader trucks over 10 years with good reputation

★ Carbon steel high-strength special steel material

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for ISUZU waste compactor trucks

Hot Tags :