The CEEC's Isuzu 700P rear loader compactor truck is modified on 4*2 drive chassis,4175mm wheelbase,equipped with 4HK1-TCG61 engine, 190 horsepower, 5193ml displacement,4-cylinder in-line turbocharged intercooler design,an MLD 6-speed gearbox,105km/h maximum speed. The garbage bin has a capacity of 10 cubic meters and is made of an arc-shaped integral steel plate. The bottom and side panels are both 4mm thick Q235 special steel, and the compression ratio reaches 1:3.4. The garbage loading and unloading system adopts PLC automatic control.

Lead Time:

60 DaysWork capacity:

10cbmTruck model:

CEEC5110GXHEngine power:

190HPEngine type:

4HK1-TCG61Axle drive:

4x2,LHDGear box:

MLD-6Q,manualRemarks:

10cbm garbage bin capacity,powerful Isuzu 4HK1 engineIsuzu 4HK1 engine truck with rear loader is a highly efficient operation vehicle designed for urban sanitation. It is equipped with a large-capacity garbage bin and an advanced compression system, which can effectively load and compress garbage. It uses a high-performance engine, is powerful, easy to operate, and can easily cope with various complex road conditions and working environments. At the same time, the vehicle also has excellent durability and stability, can run stably for a long time, and reduce maintenance costs.

Key Features:

★ Various size body from 3cbm to 25cbm,with beautiful appearance

★ ISUZU 4HK1 engine,super powerful;reliable performance. no overhaul,within 1000000km

★ Good sealing, no secondary pollution caused by sewage leakage when dumping garbage

★ Adopting electric, gas and hydraulic centralized control, with automatic and manual operation modes

★ Diffient rear flip systerm are optional

★ Can be put into 20",40"container and ship to worldwide

|

Isuzu 700P 10cbm rear loader garbage truck |

||

|

Vehicle Model: |

PT5110GXH |

|

|

Chassis Dimensions and Parameters |

Overall Dimension(L x W x H) |

7750x2350x2550mm |

|

Wheelbase: |

4175mm |

|

|

Front/ Rear Wheel Distance: |

1680/1650mm |

|

|

Front/Rear Suspension |

1110/2465mm |

|

|

Rear Axle Ratio: |

4.1 |

|

|

Weights and Capacities |

Curb Weight: |

5500Kg |

|

Payload: |

6000Kg |

|

|

GVW: |

11000Kg |

|

|

Axle Loads: |

4000/7000kg |

|

|

Engine |

Type: |

4 cylinder inline,4 strokes,water cooling,turbo inter cooling,diesel engine |

|

Engine Model: |

4HK1-TCG61 |

|

|

Max output: |

140Kw |

|

|

Displacement: |

5193ml |

|

|

Horsepower: |

190HP |

|

|

Exhaust Gas Treatment Technology: |

EGR |

|

|

Max Torque |

507N.m |

|

|

Rated speed |

2600rpm |

|

|

Maximum torque speed |

1600-2600rpm |

|

|

Transmission |

Transmission: |

MLD-6Q |

|

Forward Gear: |

6 Speed Gear |

|

|

Backward Gear: |

1 Speed Gear |

|

|

Brake |

Hydraulic Brake |

|

|

Front Drum Back Drum |

||

|

Generator |

24V-80A |

|

|

Cab |

Number of Seats: |

3 |

|

Chassis |

Drive Type: |

4x2 |

|

Tires: |

7(Including Spare Tire) |

|

|

Fuel Tank |

Number: |

1 |

|

Capacity: |

100L |

|

|

Top Parameters |

Garbage Container Capacity |

10m3 |

|

Filler Volume |

1.5m3 |

|

|

Compression ratio |

1:3.4 |

|

|

Cycling time of Filling |

≤25S |

|

|

Lifting time of Filler |

8-10S |

|

|

Time of Discharging |

≤45S |

|

|

Hydraulic System Pressure |

20Mpa |

|

|

Hydraulic system control mode |

Manual/electric integrated control |

|

|

Oil cylinder type |

Double-acting piston type |

|

|

Oil pump |

Dual gear pump |

|

|

Directional control valve |

Multiple way reversing valve |

|

|

Manipulator configuration |

Standard double barrel manipulator |

|

|

Configurations |

1 |

Power Steering System |

|

2 |

Air Conditioning |

|

|

3 |

Retro-Reflective Marking |

|

|

4 |

ABS |

|

|

5 |

Tubeless Tire |

|

|

6 |

Free Maintenance Battery |

|

Work principles

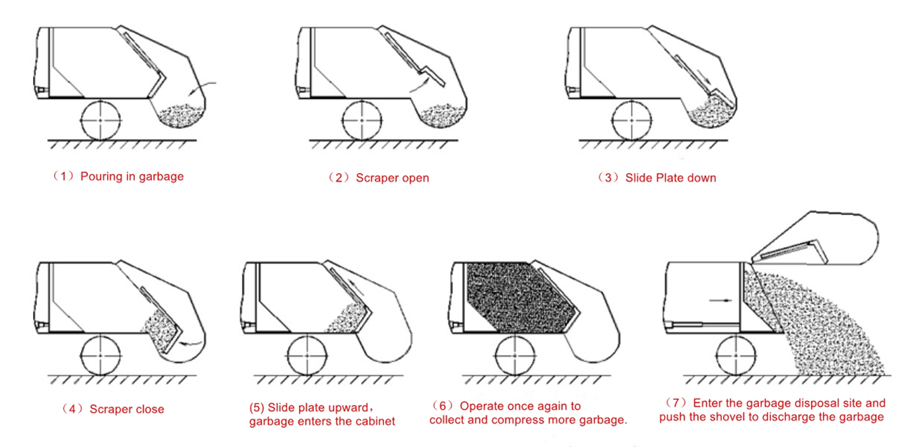

The power generated by the vehicle engine is transmitted to the oil pump through the power take-off and the transmission shaft, and the oil pump rotates to generate high-pressure oil. By operating the control switch on the multi-way reversing valve, the hydraulic oil drives the relevant cylinders to work. These cylinders drive the push shovel, scraper, skateboard and other mechanisms to complete the tasks of loading and compressing garbage. During loading, the garbage is filled into the garbage bin, and then the garbage is gradually compressed to a high-density state through the propulsion of the push shovel and the cooperation of the scraper and skateboard. When the garbage bin is full, the vehicle transports the garbage to the designated location for unloading.

This process not only improves the efficiency of garbage disposal, but also effectively reduces the volume and weight of garbage, reducing transportation costs and environmental pollution.

Operation steps

★. Preparation before operation:

◆ Check the safety of the vehicle's surrounding environment to ensure that there is no oil or water leakage in the vehicle.

◆ Check whether the hydraulic oil level is at the upper end of the level gauge to ensure that the hydraulic oil is sufficient.

◆ Get on the vehicle and start the vehicle. After the air pressure reaches the specified value, step on the clutch, press the power take-off switch, slowly release the clutch, and start the hydraulic system.

★. Loading garbage operation:

◆ Pour the garbage into the garbage bucket.

◆ Turn the operating knob to the "up" gear to keep the garbage poured into the filler bucket.

◆ Press the "one-button cycle" or "continuous cycle" button to perform actions such as scraper expansion, slide board downward, scraper scraping, and slide board upward to load the garbage into the garbage bin.

★. Compressing garbage operation:

◆ During the loading process, as the garbage increases, the shovel gradually retreats under the push of the hydraulic cylinder, while the scraper and slide board continue to move to compress the garbage.

◆ When the garbage in the garbage bin reaches the preset height, stop loading and continue to perform the compression action until the garbage is compacted to the specified density.

★. Unloading garbage operation:

◆ Switch the working mode to "unloading" mode.

◆ Long press the "filler lift" button to lift the filler to an appropriate height.

◆ Long press the "bushing shovel push" button to push the garbage out of the garbage bin.

◆ After unloading, long press the "bushing shovel retract" button to retract the pushing shovel to its original position.

◆ Single-click the "cleaning button" to perform actions such as scraper opening, sliding plate downward, scraper closing, sliding plate upward, etc. to clean the garbage in the filler.

◆ Long press the "filler lowering" button to lower the filler to its original position and confirm the locking.

★ ISUZU 4HK1 diesel engine, super powerful

★ Expert for producing ISUZU rear load trash trucks over 10 years with good reputation

★ T420 high-strength special steel material

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for ISUZU rubbish compactor trucks

Hot Tags :