CEEC's Isuzu 700P 10cbm rear loader compactor is used for garbage collection and disposal.With 4175mm wheelbase,4HK1 190HP engine,Euro 6 diesel 5193ml emission,Isuzu MLD 6-shift gearbox,with A/C,USB,direction assistance,3 seats.The upper body is a 10cbm garbage bin, rear is a bucket flip mechanism, there are 4 methods to operate the truck's loading and unloading.

Lead Time:

60 DaysWork capacity:

10cbmTruck model:

CEEC5110ZYSEngine power:

190HPEngine type:

Isuzu 4HK1-TCG61Axle drive:

4x2,LHDGear box:

Isuzu MLD 6-shift gearbox,manualRemarks:

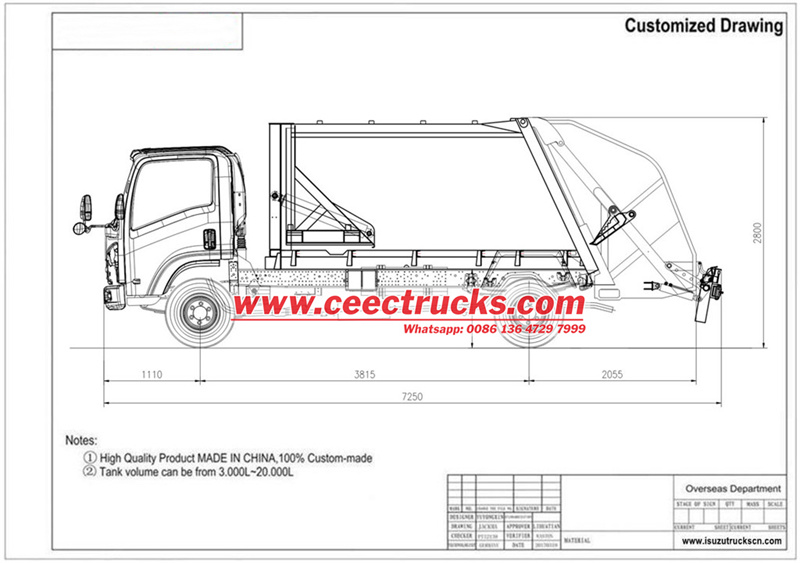

10cbm garbage bin,with 4 operation methodsThe ISUZU 10-cubic-meter waste compactor truck is a high-efficiency equipment specifically designed for urban waste management. It employs advanced compression technology to significantly reduce the volume of garbage, thereby enhancing transportation efficiency, decreasing the number of transport trips, and lowering operational costs. Built on the Isuzu NPR chassis, this vehicle is equipped with a 190hp 4HK1 engine and a six-speed transmission, offering robust power performance and stable driving capabilities. With its compact design and easy operation, the ISUZU 10CBM hydraulic garbage compactor is suitable for garbage collection and transportation in various environments, including cities and townships.

● China best Isuzu waste compactor truck factory

● More than 30 years professional manufacturer experience

● Be designed according to your requirements

● Professional sales team which will help you to choose suitable truck.

● We can offer your a good after-sell service

Product Specifications:

|

ISUZU 10CBM REAR LOAD GARBAGE TRUCK SPECIFICATIONS |

||

|

Chassis Model |

QL1110AN Driving type: 4*2 left hand driving |

|

|

Engine |

Make: ISUZU |

|

|

Diesel 4-stroke direct injection diesel engine |

||

|

Engine model:4HK1-TCG61, Euro 6 emission standard |

||

|

4-cylinder in-line with water cooled, turbocharged and intercooler |

||

|

Maximum output: 189HP/139KW |

||

|

Maximum torque: 507 Nm |

||

|

Displacement: 5.2 L |

||

|

Transmission |

ISUZU MLD, 6 forwards and 1 reverse, manual |

|

|

Chassis |

Frame: U-profile parallel ladder frame and reinforced subframe |

|

|

Front suspension:8 pcs semi-elliptic leaf spring |

||

|

Rear suspension:10+6 pcs semi-elliptic lea spring |

||

|

Fuel tank: 100 L capacity with locking fuel cap |

||

|

Steering |

Power steering, hydraulic steering with power assitance |

|

|

Brakes |

Service brake: dual circuit compressed air brake |

|

|

Parking brake (emergency brake): spring energy, compressed air operating on front shaft and rear wheels |

||

|

ABS |

||

|

Wheels & Tyres |

Tire: 7 pcs 235/75R17.5 |

|

|

Optional:8.25R20 |

||

|

Driver's Cab |

ISUZU NPR wide cab, with three seats, A/C, electric glass, central lock |

|

|

Dimensions mm |

Wheel base |

4175 MM |

|

Overall length |

7400 MM |

|

|

Overall width |

2300 MM |

|

|

Overall height |

2640 MM |

|

|

Weight kg |

Curb weight |

6900 KG |

|

Rated Loading Capacity |

4000 KG |

|

|

Gross vehicle weight(GVW) |

11000 KG |

|

|

Front axle loading capacity |

4000 KG |

|

|

Rear axle loading capacity |

7000 KG |

|

|

Compactor Body |

Volume of body(m3) |

10 |

|

Volume of filler(m3) |

2 |

|

|

Time of one filling cycle(s) |

≤25 |

|

|

Lifting time of filler (s) |

8-10 |

|

|

Time of discharge (s) |

≤40 |

|

|

Pressure of hydraulic system (Mpa) |

18 |

|

|

Front/rear sewage capacity (L) |

250+150 |

|

|

Control system |

CAN-bus (electrical) and manual (hydraulic) |

|

Isuzu NPR rear loader truck Required Manufacturing Standards:

1. High-tensile steel processing technology

——Material selection and forming: High-tensile steel is used, and precise laser/plasma cutting and bending are performed for different parts (such as floor 4mm, side panel 3mm).

——Welding technology: Full-seam welding process, using automated welding equipment to ensure a firm connection between the U-shaped support (4mm thick) and the body structure.

2. Hydraulic system manufacturing and integration

——Precision machining: The hydraulic cylinder adopts a double-acting design, the inner wall is chrome-plated for corrosion protection, and the oil pipe must meet the standard of pressure resistance of 4 times the system working pressure.

——Pressure test: Strict pressure test of the hydraulic system (170 bar working pressure) to ensure no leakage and long-term reliability.

——PTO drive integration: Adapt to the original truck PTO or customized drive system to ensure seamless matching of the hydraulic pump (30–80 cm³/rev) and the chassis power.

3. Electronic control system development

——PLC automation control: design full-automatic/semi-automatic/manual operation modes, integrate emergency stop button, communication buzzer and safety warning device.

——Circuit isolation: independent of truck circuit to ensure control system stability and safety.

4. Coating and anti-corrosion process

——Surface treatment: sandblasting to remove rust and degreasing pretreatment to ensure the cleanliness of the substrate.

——Multi-layer coating: two coats of primer + one coat of topcoat, dry film thickness ≥ 60 microns, to enhance weather resistance and corrosion resistance

★ ISUZU 4HK1 diesel engine, super powerful

★ Expert for producing ISUZU rear load trash trucks over 10 years with good reputation

★ T420 high-strength special steel material

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for ISUZU rubbish compactor trucks

Hot Tags :