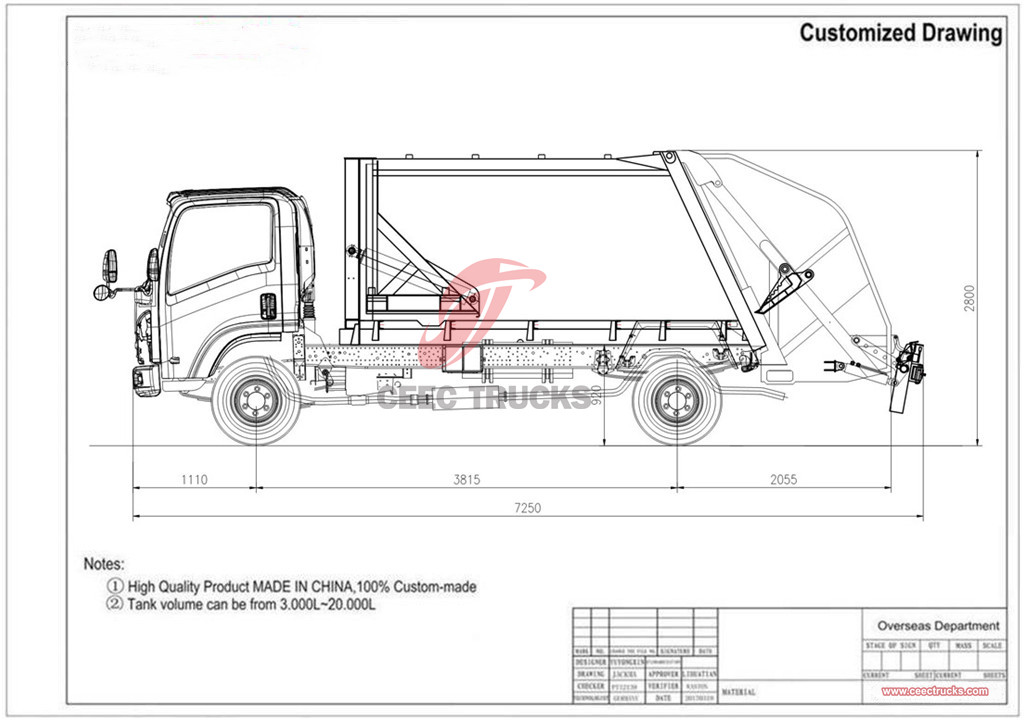

Isuzu 700P 8 cubic garbage compactor truck, modified based on Isuzu 700P chassis, wheelbase 3815mm, Isuzu 4HK1-TCG61 engine, 139Kw, Euro 6 emission, displacement 5193ml. The vehicle compression volume is 8cbm, made of carbon steel. The vehicle garbage loading and unloading has four operating controls, including the electric control box in the cab, the manual hydraulic operating lever on the driver's side, the electric control box on the left side of the tailgate, and the manual operating lever on the right side of the tailgate, which improves work efficiency.

Work capacity:

8CBMTruck model:

CEEC511GZXEngine power:

190HPEngine type:

4HK1-TCG61Axle drive:

4X2,LHDGear box:

Isuzu MLD-6 speed,manualRemarks:

Powerful Isuzu chassis and efficient compression capabilityThe Isuzu NPR Republic Service Rear Loader is a garbage collection truck specifically designed for urban sanitation, based on the Isuzu 700P chassis and equipped with an advanced garbage compression system and multiple operation control modes. The vehicle boasts efficient garbage loading and transportation capabilities, making it suitable for various scenarios such as city streets, public areas, and garbage transfer stations. With its large compression volume and flexible operation, it can significantly enhance garbage collection efficiency, contributing to the urban environmental protection cause. Additionally, the vehicle complies with the EURO 6 emission standard, embodying the design philosophy of balancing environmental protection and efficiency, and serving as a reliable assistant in the field of urban garbage disposal.

● 30 years experience on ISUZU rear loader truck designing

● 50 units Isuzu refuse compactors in stock

● Fast delivery time, Quick 10 days shipping time

● 24 months long guarantee time assurance

● CKD, SKD parts service, Container shipping, Save freight

● OEM customized service, print your company logo

|

Isuzu 700P 8cbm rear loader compactor |

||

|

Vehicle Model: |

CEEC5110GYS |

|

|

Chassis Dimensions and Parameters |

Overall Dimension(L x W x H) |

7600x2300x2450mm |

|

Wheelbase: |

3815mm |

|

|

Front/ Rear Wheel Distance: |

1680/1650mm |

|

|

Front/Rear Suspension |

1110/2675mm |

|

|

Rear Axle Ratio: |

4.1 |

|

|

Weights and Capacities |

Curb Weight: |

6750Kg |

|

GVW: |

10550Kg |

|

|

Axle Loads: |

4000/6550kg |

|

|

Engine |

Type: |

4 cylinder inline,4 strokes,water cooling,turbo inter cooling,diesel engine |

|

Engine Model: |

Isuzu 4HK1-TCG61 |

|

|

Max output: |

139Kw |

|

|

Displacement: |

5193ml |

|

|

Horsepower: |

190HP |

|

|

Exhaust Gas Treatment Technology: |

EGR |

|

|

Max Torque |

507N.m |

|

|

Rated speed |

2600rpm |

|

|

Maximum torque speed |

1600-2600rpm |

|

|

Transmission |

Transmission: |

Isuzu MLD-6 speed,manual |

|

Brake |

Hydraulic Brake |

|

|

Front Drum Back Drum |

||

|

Generator |

24V-80A |

|

|

Cab |

Number of Seats: |

3 |

|

Chassis |

Drive Type: |

4x2 |

|

Tires: |

7(Including Spare Tire) |

|

|

Fuel Tank |

Number: |

1 |

|

Capacity: |

100L |

|

|

Top Parameters |

Garbage Container Capacity |

8m3 |

|

Compression ratio |

1:3.4 |

|

|

Cycling time of Filling |

≤25S |

|

|

Lifting time of Filler |

8-10S |

|

|

Time of Discharging |

≤45S |

|

|

Hydraulic System Pressure |

16Mpa |

|

|

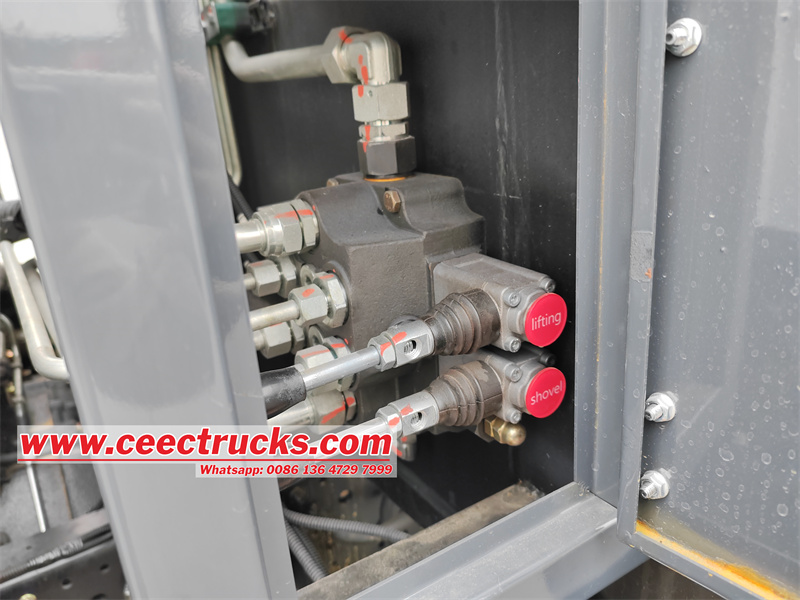

Hydraulic system control mode |

Manual/electric integrated control |

|

|

Oil cylinder type |

Double-acting piston type |

|

|

Oil pump |

Dual gear pump |

|

|

Directional control valve |

Multiple way reversing valve |

|

|

Manipulator configuration |

Standard double barrel manipulator |

|

|

Configurations |

1 |

Power Steering System |

|

2 |

Air Conditioning |

|

|

3 |

Retro-Reflective Marking |

|

|

4 |

ABS |

|

|

5 |

Tubeless Tire |

|

|

6 |

Free Maintenance Battery |

|

Garbage Collection and Compression System

Compression Volume: With a compression volume design of 8 cubic meters, the garbage collection efficiency is greatly improved.

Operation Control: The vehicle is equipped with four operation control methods, including an electric control box inside the cab, a manual hydraulic operating lever on the driver's side, an electric control box on the left side of the tailgate, and a manual operating lever on the right side of the tailgate. The design of these four operation control methods fully considers the driver's operating habits and the needs of different working environments, thereby improving work efficiency.

Detailed Explanation of the Working Principle and Loading Steps of the Rear Loader

The compressed garbage truck is a highly efficient and technologically advanced sanitary garbage truck that not only transports garbage but also compresses household waste into blocks, making the garbage collection process more environmentally friendly and convenient.

Components of the Compressed Garbage Truck:

The compressed garbage truck mainly consists of a dedicated chassis for sanitary vehicles (such as Dongfeng, Foton, Changan, and other brands) and an upper assembly. The upper assembly includes the compartment, pusher, loader, tilting frame, hydraulic system, electronic control system, and other main accessories.

Working Principle of the Garbage Compactor Truck:

● Hydraulic Drive: The loading, compression, and unloading processes of the compressed garbage truck are all driven hydraulically and completed through specialized mechanisms. The power of the vehicle's engine is transmitted to the oil pump through a power take-off, and the rotating oil pump generates high-pressure oil. By operating the relevant control switches on the multi-way directional valve, the hydraulic oil drives the relevant cylinders to work, which in turn drive the mechanisms to complete the tasks of loading, compressing, or unloading garbage.

● Automatic Holding in Neutral Position: When the multi-way directional valve handle is not operated, it automatically holds in the neutral position, and the hydraulic oil discharged by the oil pump returns to the tank through the directional valve.

● Working Pressure Limitation: The maximum working pressure of the hydraulic system is 16 MPa, which is limited by the relief valve on the multi-way directional valve. When the system pressure exceeds 16 MPa, the hydraulic oil flows back to the tank through the relief valve.

Loading Steps of the Rear Loader Garbage Truck:

● Scraper Preparation: When the loading hopper is filled with garbage, the scraper opens and prepares to insert into the loose garbage.

● Initial Compression: The slide plate drives the scraper to move downward together, inserting into the garbage for crushing and initial compression.

● Further Compaction: The scraper rotates forward to further compact the garbage.

● Garbage Loading: After the scraper is in place, it moves upward along with the slide plate, compacting and loading the garbage into the garbage compartment, and then returns to the starting position. During the continuous pressing and filling of the garbage, the pusher gradually retreats under the action of the extrusion force, allowing the garbage to evenly fill the entire garbage compartment.

● Sealing the Garbage Compartment: After the garbage truck is fully loaded, the garbage compartment is completely sealed, preventing environmental pollution during transportation.

● Unloading the Garbage: When the garbage truck unloads the garbage at the disposal (or landfill) site, it first lifts the loader, opens the rear end of the garbage compartment, and the pusher, originally stopped at the front end of the garbage compartment, moves backward along the horizontal direction, pushing the garbage out of the compartment.

★ ISUZU 4HK1 diesel engine, super powerful

★ Expert for producing ISUZU rear loader trucks over 10 years with good reputation

★ T420 high-strength special steel material

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for ISUZU waste compactor trucks

Hot Tags :