The Isuzu 8cbm garbage compactor truck is modified on the Isuzu NKR 600P chassis, with 3815mm wheelbase, 4KH1CN6LB 120HP engine, 2999ml displacement, EURO 6 emission, Isuzu MSB 5-speed gearbox,maximum speed 110Km/h, the upper body is an 8 cubic garbage bin, with sides 4mm and bottom 5mm thickness, anti-rust treatment, and is operated and controlled by Taiwan Yonghong PLC electronic control system and hydraulic manual operation system, including 1 set of electronic control operation buttons in the cab and 1 set on the left side of the tailgate (2 sets in total), and 1 set of hydraulic manual operation device behind the cab.

Work capacity:

8CBMTruck model:

CEEC5070GRZEngine power:

120HPEngine type:

ISUZU 4KH1CN6LBAxle drive:

4X2,LHDGear box:

ISUZU MSB 5-speed,manualRemarks:

8cbm garbage bin,with 3 operation modesThe Philippine Isuzu 8 cbm Super Garbage Compactor Truck is a robust and efficient waste management vehicle designed for heavy-duty operations. It features an 8-cubic-meter garbage compactor body with a durable 4mm side and 5mm bottom thickness, ensuring high strength and longevity. Equipped with an advanced compactor system, it maximizes waste compression, increasing load capacity and reducing collection frequency. Powered by a reliable Isuzu 4KH1 engine, the truck offers excellent fuel efficiency and performance. Its ergonomic design includes user-friendly controls and safety features, making it ideal for urban and industrial waste collection.

● More than 30 years professional manufacturer experience

● More than 500 workers, large and advanced production

● We have strong professional design team

● Promptly delivery. any order is welcome

● 24 months long guarantee time assurance

Key Features:

★ Various size body from 3cbm to 25cbm,with beautiful appearance

★ ISUZU 4KH1 engine,super powerful;reliable performance. no overhaul,within 1000000km

★ Good sealing, no secondary pollution caused by sewage leakage when dumping garbage

★ Adopting electric, gas and hydraulic centralized control, with automatic and manual operation modes

★ Diffient rear flip systerm are optional

★ Can be put into 20",40"container and ship to worldwide

Product Parameters

|

Isuzu 600P 8cbm rear loader compactor truck |

||

|

Cabin |

Driving type 4x2, Left Hand Drive. |

|

|

Isuzu 600P single row,2 seats,with A/C,USB,direction assistance. |

||

|

Vehicle Main Dimensions |

Overall dimensions (L x W x H) |

7150*2210*2640mm |

|

Wheel base |

3815mm |

|

|

Overhang (front/rear) |

1110/2225mm |

|

|

Weight in KGS |

GVW |

7300kg |

|

Curb weight |

4020kg |

|

|

Front axles loading capacity |

2580kg |

|

|

Rear axles loading capacity |

4720kg |

|

|

Max. driving speed(km/h) |

110km/h |

|

|

Engine |

Brand |

ISUZU |

|

Model |

4KH1CN6LB |

|

|

Type |

4-stroke direct injection, 4-cylinder in-line with water cooling, turbo-charging and inter-cooling,diesel |

|

|

Horse Power |

120 HP/88kw |

|

|

Max torque |

290N·m |

|

|

Displacement |

2999ml |

|

|

Emission standard |

Euro VI |

|

|

Gearbox |

Isuzu MSB 5 forwards &1 reverse |

|

|

Clutch |

Diaphragm spring clutch |

|

|

Steering Gear |

Power steering |

|

|

Tire |

7.00R16 All radial tires with one spare, 7 pieces |

|

|

Compression garbage box body system |

||

|

Body Volume |

8CBM |

|

|

Material |

Carbon steel |

|

|

Thickness |

Side 4mm, Bottom 5mm |

|

|

Cycle Time of Filling |

25-30s |

|

|

Lifting Time of Filler |

8-10s |

|

|

Time of Discharging |

≤40s |

|

|

Working Pressure |

16 MPA |

|

|

Hydraulic system |

||

|

Shovel cylinder |

1 |

|

|

Scraper cylinder |

2 |

|

|

Slide plate cylinder |

2 |

|

|

Rear flip cylinder |

2 |

|

|

Lifting cylinder |

2 |

|

|

Hydraulic tank |

150L |

|

|

Hydraulic oil pump |

Hefei Wanye Oil Pump |

|

|

Multi-way valve |

Yangzhou Zhongmei multi-way valve |

|

|

Electric control system |

||

|

Operating system |

Taiwan Yonghong PLC electric control system and manual operation device |

|

|

Electronic control operation button |

1 set in the cabin, 1 set at the left of the tailgate (2 sets total) |

|

|

Manual operation device |

1 set behind cab |

|

|

Composed by hermetic garbage tank, hydraulic system, operation system. The entire truck is hermetic, can automatically compress and dump the garbage .and the sewage generated in the process of the compression all go into the sewage tank. |

||

Product Applications

This Isuzu 8cbm garbage compactor special vehicle is a carefully modified version of the Isuzu NKR 600P chassis, whose chassis is well known for its reliability and versatility. The wheelbase is 3815 mm, which provides excellent stability and maneuverability. The vehicle is powered by a powerful 4KH1CN6LB engine that produces an impressive 120 horsepower. The engine is designed to provide ample torque and power, ensuring that the truck can handle large amounts of waste with ease. The engine with a displacement of 2999 ml is not only powerful but also fuel-efficient, making it an environmentally friendly choice for waste management operations. The upper body is an 8cbm garbage box body with a curved design and anti-corrosion treatment.

The upper body of the vehicle adopts a garbage bin with a capacity of 8 cubic meters, and the box body structure is designed to be sturdy and durable. The side panel thickness of the box body is 4mm and the bottom panel thickness is 5mm, ensuring its stability and carrying capacity in high-load working environments. The cabinet adopts **arc design**, which not only improves the overall aesthetics, but also effectively reduces garbage residue, making it easier to clean and maintain.

In order to enhance the corrosion resistance of the cabinet, the cabinet surface has been professionally **rust-proofed**, which can effectively cope with humid and corrosive environments and extend the service life of the equipment. This design makes the cabinet more adaptable to various complex working conditions and ensures long-term stable operation.

The truck boasts advanced control systems that facilitate easy and efficient operation. It features a Taiwan Yonghong PLC (Programmable Logic Controller) electrical control system, which allows for precise and reliable automation of the garbage compaction process. There are two sets of electrical control buttons strategically placed for operator convenience: one set inside the driver's cab and another set on the left side of the tailgate. Additionally, the truck is equipped with a hydraulic manual operation device located at the rear of the cab, providing an alternative method of controlling the garbage compaction functions in case of electrical system failure or for manual override. This dual control system ensures that the truck can be operated smoothly and efficiently, meeting the diverse needs of waste management operations.

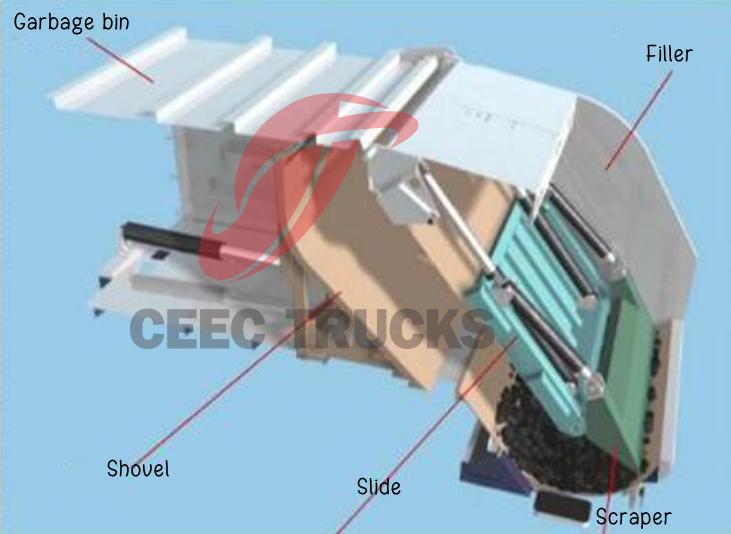

Working steps of Isuzu rear loader garbage truck

1. Load the garbage into the hopper in the filler.

2. The scraper opens, and the slide drives the scraper to move downward together, inserting into the garbage to crush the garbage and perform the first compression.

3. The scraper rotates forward to further compact the garbage.

4. After the scraper is in place, the slide drives the scraper to move upward, compact the garbage, and load it into the garbage compartment. The scraper and the slide return to the initial position. The entire working process can be automatically or manually controlled.

5. After continuous loading of garbage, the garbage fills the entire garbage compartment.

6. When the garbage truck unloads the garbage, lift the filler, move the shovel backward, and push the garbage out of the garbage compartment in the horizontal direction.

7. After the garbage is pushed out, put down the filler to complete the unloading process.

★ Japanese ISUZU diesel engine, super powerful

★ Expert for producing rear loader garbage compactor truck over 10 years with good reputation

★ Carbon steel material T420

★ 12 months free fast moving spare parts

★ All English version control box, panel, and owner's manual, for easy understanding

★ Training service for compression garbage trucks

Hot Tags :